Understanding Lean Manufacturing in Nigeria: A Practical Overview

Lean manufacturing in Nigeria represents a systematic approach that Nigerian manufacturers are increasingly adopting to remain competitive in today’s challenging economic landscape. This methodology focuses on eliminating waste while maximizing customer value through continuous improvement processes. For Nigerian companies, understanding lean principles isn’t just about copying foreign practices—it’s about adapting proven strategies to local market conditions and cultural contexts.

The foundation of lean thinking rests on five core principles that resonate particularly well with Nigerian business values. These include defining value from the customer’s perspective, mapping the value stream, creating flow, establishing pull systems, and pursuing perfection. Nigerian manufacturers who grasp these concepts often find them aligning naturally with traditional business wisdom that emphasizes efficiency and resourcefulness.

What makes lean manufacturing particularly relevant for Nigeria is its emphasis on doing more with less. Given the country’s economic challenges and resource constraints, lean methodologies offer practical solutions for maximizing output while minimizing waste. Companies that implement these strategies often report significant improvements in productivity, quality, and employee engagement within the first year of implementation.

Why Nigerian Manufacturers Must Embrace Lean for Competitive Advantage

Manufacturing efficiency strategies in Nigeria have become critical as local companies face increasing pressure from both domestic and international competitors. The Nigerian manufacturing sector contributes approximately 9% to the country’s GDP, yet many companies operate far below their potential capacity. This gap presents both a challenge and an opportunity for manufacturers willing to adopt lean methodologies.

Global competition has intensified across all sectors, from textiles to food processing to automotive assembly. Nigerian manufacturers who continue using traditional production methods often find themselves struggling with high operational costs, quality issues, and customer dissatisfaction. Meanwhile, companies that implement lean principles typically reduce production costs by 20-30% while improving quality metrics substantially.

The economic benefits extend beyond individual companies to the broader Nigerian economy. When manufacturers operate more efficiently, they create more jobs, generate higher tax revenues, and contribute to export growth. This ripple effect makes lean manufacturing not just a business imperative but a national economic strategy that supports Nigeria’s industrialization goals and Vision 2030 objectives.

Novatia Consulting’s Proven Approach to Lean Manufacturing in Nigeria

Novatia Consulting has developed a comprehensive methodology specifically tailored for Nigerian manufacturers seeking sustainable lean transformation. Our approach begins with a thorough assessment of current operations, identifying specific areas where lean manufacturing principles can deliver immediate impact. We understand that Nigerian companies have unique challenges, from supply chain disruptions to skilled labor shortages, and our solutions address these realities head-on.

Our implementation strategy follows a phased approach that minimizes disruption to ongoing operations. We start with pilot programs in specific production areas, allowing companies to see tangible results before committing to organization-wide changes. This methodical approach has helped over 150 Nigerian manufacturers achieve measurable improvements in productivity, quality, and profitability within six months of program initiation.

What sets Novatia apart is our deep understanding of Nigerian business culture and operational environment. We don’t simply transplant foreign lean practices; instead, we adapt proven methodologies to work within local contexts. Our team includes experienced consultants who have successfully implemented lean programs across various Nigerian industries, from cement production to pharmaceutical manufacturing, ensuring that our guidance is both practical and culturally relevant.

Key Principles of Lean and Their Application in Nigerian Industries

Process improvement in Nigerian industries begins with understanding how lean principles translate into practical operational changes. The first principle, identifying customer value, requires manufacturers to honestly assess what their customers truly want versus what they’re currently delivering. Nigerian companies often discover that customers value reliability and consistency more than premium features, leading to focused improvement efforts.

Value stream mapping becomes particularly powerful in the Nigerian context where supply chains are complex and often unreliable. By visualizing the entire production process from raw materials to finished goods, manufacturers can identify bottlenecks that are uniquely Nigerian—such as power outages, transportation delays, or customs clearance issues. This visibility enables targeted interventions that address root causes rather than symptoms.

Creating flow in Nigerian manufacturing requires adapting lean principles to local infrastructure realities. This might mean implementing flexible production schedules that account for power instability, or designing buffer strategies that protect against supply disruptions. Companies that successfully apply these adapted principles often find they become more resilient and responsive than competitors who ignore local conditions.

Process Improvement in Nigerian Industries: Where to Begin

Starting process improvement initiatives in Nigerian manufacturing requires a strategic approach that balances ambition with practicality. Most successful transformations begin with a focus on the most critical production constraints—often power management, material flow, or quality control systems. These areas typically offer the quickest wins and help build momentum for broader organizational change.

The initial assessment phase should involve frontline workers who understand daily operational challenges. Nigerian manufacturers often underestimate the valuable insights their experienced operators possess about inefficiencies and potential solutions. By engaging these team members early in the process, companies can identify improvement opportunities that management might overlook while building essential buy-in for upcoming changes.

Prioritizing improvements based on impact and feasibility ensures sustainable progress. Rather than attempting to fix everything simultaneously, successful Nigerian manufacturers focus on 2-3 critical areas where improvements will cascade throughout the organization. This focused approach allows companies to develop internal capabilities while demonstrating clear value from lean investments, making it easier to secure continued support for expansion efforts.

Eliminating Waste: Core to Manufacturing Efficiency Strategies in Nigeria

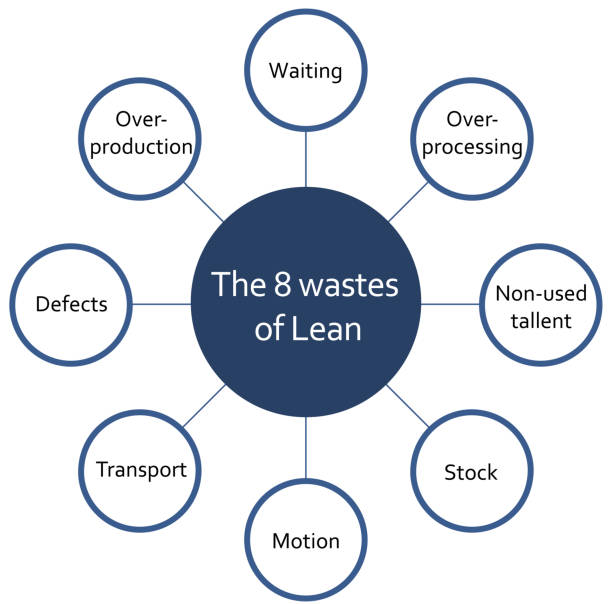

Waste elimination forms the heart of manufacturing efficiency strategies in Nigeria, where resource optimization directly impacts profitability and competitiveness. The eight types of waste identified in lean methodology—overproduction, waiting, transportation, inappropriate processing, unnecessary inventory, unnecessary motion, defects, and underutilized human potential—manifest differently in Nigerian manufacturing environments but remain equally destructive to operational performance.

Overproduction waste particularly affects Nigerian manufacturers who often build large inventory buffers to compensate for supply chain uncertainties. While some buffer is necessary given local conditions, excessive inventory ties up working capital and masks underlying process problems. Successful companies learn to balance supply chain risks with inventory optimization, often achieving 30-40% inventory reductions without compromising customer service levels.

The most overlooked waste in Nigerian manufacturing is underutilized human potential. Many companies have skilled workers whose knowledge and creativity aren’t fully tapped for improvement initiatives. When manufacturers create systems for capturing and implementing employee suggestions, they often discover innovative solutions to long-standing problems. This participatory approach to waste elimination creates sustainable improvements while building stronger organizational culture.

Common Challenges in Lean Implementation and How Nigerian Firms Can Overcome Them

Resistance to change represents the most significant challenge Nigerian manufacturers face when implementing lean methodologies. This resistance often stems from past experiences with failed improvement initiatives or concerns about job security. Successful companies address these concerns through transparent communication about lean objectives and by involving employees in solution development rather than simply imposing new processes.

Infrastructure limitations pose unique challenges for Nigerian manufacturers seeking to implement lean manufacturing principles. Power instability, transportation difficulties, and supply chain disruptions can undermine lean initiatives that assume stable operating conditions. Smart companies adapt lean tools to work within these constraints, developing flexible systems that maintain efficiency even during infrastructure disruptions.

Skills gaps in both management and frontline workers can slow lean implementation progress. Many Nigerian manufacturers lack internal expertise in lean methodologies, statistical process control, or continuous improvement techniques. Partnering with experienced consulting firms like Novatia Consulting helps companies build internal capabilities while avoiding common implementation pitfalls that can derail transformation efforts.

Case Study Insights: Lean Success Stories from Nigerian Manufacturing

A leading Nigerian food processing company partnered with Novatia Consulting to implement lean manufacturing across three production facilities. The initial assessment revealed significant waste in material handling, excessive work-in-process inventory, and quality issues that required rework. Through systematic application of lean principles, the company reduced production lead times by 45% while improving overall equipment effectiveness from 65% to 87%.

The transformation began with value stream mapping exercises that identified critical bottlenecks in the packaging department. By reorganizing workflow patterns and implementing pull systems, the company eliminated transportation waste and reduced inventory levels. Employee engagement initiatives generated over 200 improvement suggestions in the first year, with 75% being implemented successfully.

Financial results exceeded expectations, with the company achieving 28% reduction in production costs and 15% improvement in customer satisfaction scores. These improvements enabled the company to expand into new markets while maintaining competitive pricing. The success attracted attention from other industry players, establishing the company as a lean manufacturing benchmark within Nigerian food processing sector.

How Lean Manufacturing in Nigeria Drives Supply Chain Transformation

Supply chain transformation through lean manufacturing in Nigeria requires understanding the unique complexities of local logistics networks. Nigerian manufacturers often deal with multiple suppliers across different states, each with varying reliability levels and quality standards. Lean principles help companies develop supplier partnerships based on mutual improvement rather than traditional adversarial relationships.

Just-in-time delivery, a cornerstone of lean manufacturing, must be adapted for Nigerian conditions where transportation infrastructure and customs processes can create unpredictable delays. Successful companies implement modified pull systems that account for these realities while still reducing inventory waste. This balanced approach often results in 20-25% inventory reductions without compromising production continuity.

Supplier development becomes crucial for sustainable lean implementation in Nigeria. Rather than simply switching to new suppliers when problems arise, successful manufacturers invest in helping existing suppliers improve their capabilities. This collaborative approach strengthens the entire supply network while reducing switching costs and building long-term competitive advantages that are difficult for competitors to replicate.

The Role of Leadership in Sustaining Manufacturing Efficiency Strategies in Nigeria

Leadership commitment determines whether manufacturing efficiency strategies in Nigeria succeed or fail over the long term. Senior executives must demonstrate genuine commitment to lean principles through their decisions, resource allocation, and daily behaviors. When leaders consistently prioritize short-term financial results over process improvement investments, lean initiatives inevitably lose momentum and credibility.

Effective lean leadership in Nigerian manufacturing requires balancing global best practices with local cultural sensitivity. Leaders must understand how to motivate teams within Nigerian cultural contexts while maintaining discipline around lean standards and continuous improvement expectations. This cultural intelligence often determines whether improvement initiatives take root or remain superficial compliance exercises.

Developing internal lean leadership capabilities ensures sustainability beyond initial implementation phases. Companies that invest in training their own managers and supervisors in lean principles create self-reinforcing improvement cultures. These internal champions understand both lean methodologies and local operational realities, making them more effective at sustaining improvements and driving further innovation.

Workforce Training and Culture Shift: Essential for Process Improvement in Nigerian Industries

Cultural transformation represents the most critical yet challenging aspect of process improvement in Nigerian industries. Traditional hierarchical structures and risk-averse attitudes can conflict with lean principles that emphasize employee empowerment and continuous experimentation. Successful transformations require patient, consistent effort to shift mindsets and behaviors throughout the organization.

Training programs must be designed specifically for Nigerian audiences, incorporating local examples and addressing cultural concerns about change. Generic lean training materials often fail to resonate with Nigerian workers who need to understand how these concepts apply within their specific work environment. Interactive training approaches that encourage questions and discussion tend to be more effective than lecture-based programs.

Building a continuous improvement culture requires celebrating small wins and recognizing employee contributions publicly. Nigerian workers often respond positively to recognition and peer acknowledgment, making these cultural practices powerful tools for reinforcing desired behaviors. Companies that integrate improvement activities into their regular performance management and reward systems see better long-term sustainability of lean initiatives.

Digital Tools Supporting Lean Manufacturing in Nigeria’s Factories

Technology integration amplifies the impact of lean manufacturing in Nigeria by providing real-time visibility into production processes and enabling data-driven decision making. Modern manufacturing execution systems help Nigerian companies track key performance indicators, identify bottlenecks quickly, and coordinate improvement efforts across multiple production lines or facilities.

Mobile technology particularly benefits Nigerian manufacturers by enabling remote monitoring and coordination despite infrastructure limitations. Plant managers can track production metrics, communicate with suppliers, and coordinate maintenance activities using smartphones and tablets, even during power outages. This flexibility proves especially valuable for companies operating multiple shifts or facilities in different locations.

Cloud-based analytics platforms help Nigerian manufacturers benchmark their performance against industry standards while protecting sensitive operational data. These tools enable small and medium enterprises to access sophisticated analysis capabilities previously available only to large corporations. The insights generated often reveal improvement opportunities that weren’t visible through traditional manual tracking methods.

Cost Reduction vs. Value Creation: Balancing Lean Priorities in Nigeria

Balancing cost reduction with value creation requires Nigerian manufacturers to think strategically about lean implementation priorities. While immediate cost savings often drive initial interest in lean methodologies, sustainable competitive advantage comes from creating superior customer value through improved quality, reliability, and responsiveness. Companies that focus solely on cost cutting often miss opportunities for revenue growth and market expansion.

Value creation in the Nigerian market often centers on reliability and consistency rather than premium features or cutting-edge innovation. Customers typically prioritize suppliers who can deliver products on time, meet quality specifications consistently, and provide responsive service support. Lean manufacturing excels at improving these fundamental performance dimensions while simultaneously reducing costs.

The most successful Nigerian manufacturers use lean principles to free up resources that can be reinvested in growth initiatives. Rather than simply dropping cost savings to the bottom line, these companies invest in new product development, market expansion, or capacity increases. This reinvestment strategy creates sustainable competitive advantages while demonstrating lean manufacturing’s contribution to long-term business success.

How Novatia Consulting Helps Manufacturers Achieve Sustainable Lean Results

Novatia Consulting’s approach to sustainable lean results focuses on building internal capabilities rather than creating dependency on external consultants. Our methodology emphasizes knowledge transfer and skills development, ensuring that client organizations can continue improving independently after our engagement concludes. This philosophy has helped numerous Nigerian manufacturers maintain momentum and achieve continued improvements years after initial implementation.

Our support extends beyond technical training to include change management and cultural transformation guidance. We understand that sustainable lean manufacturing requires more than process changes—it demands new ways of thinking and working throughout the organization. Our consultants work closely with client leadership teams to develop communication strategies, reward systems, and organizational structures that reinforce lean behaviors.

Post-implementation support includes regular check-ins, refresher training sessions, and assistance with advanced lean tools as companies mature in their improvement journey. This ongoing partnership approach helps prevent backsliding while enabling companies to tackle increasingly sophisticated improvement challenges. Many of our clients have achieved recognition as industry leaders in operational excellence within 2-3 years of beginning their lean journey.

The Future of Lean Manufacturing in Nigeria: Trends and Opportunities

The future of lean manufacturing in Nigeria looks increasingly promising as more companies recognize its potential for competitive advantage. Government initiatives supporting local manufacturing, combined with growing domestic market demand, create favorable conditions for manufacturers willing to invest in operational excellence. Companies that establish lean capabilities now will be better positioned to capitalize on these emerging opportunities.

Industry 4.0 technologies offer exciting possibilities for enhancing lean manufacturing effectiveness in Nigeria. Internet of Things sensors, artificial intelligence, and machine learning can provide unprecedented visibility into production processes while automating routine improvement activities. Nigerian manufacturers that combine lean principles with digital technologies often achieve improvement rates that exceed traditional lean implementations.

The next decade will likely see lean manufacturing become a standard requirement for competing effectively in Nigerian markets. As customer expectations rise and competition intensifies, manufacturers without lean capabilities will find it increasingly difficult to maintain market share. Early adopters are already building significant advantages that will compound over time, making immediate action essential for long-term competitiveness.

Frequently Asked Questions About Lean Manufacturing in Nigeria

How long does it take to implement lean manufacturing in Nigeria? Lean manufacturing implementation typically takes 12-18 months for initial results, with full transformation occurring over 2-3 years. Nigerian manufacturers often see measurable improvements within 6 months when working with experienced consultants like Novatia Consulting.

What are the main barriers to lean manufacturing in Nigeria? The primary barriers include resistance to change, infrastructure limitations like power instability, skills gaps, and supply chain unreliability. However, successful Nigerian companies adapt lean principles to work within these constraints.

Can small Nigerian manufacturers benefit from lean manufacturing? Yes, small manufacturers often see proportionally greater benefits from lean manufacturing since they can implement changes more quickly. The key is starting with focused improvements in critical areas rather than attempting comprehensive transformation immediately.

How much does lean manufacturing implementation cost in Nigeria? Implementation costs vary based on company size and scope, but most Nigerian manufacturers recover their investment within 12-15 months through improved efficiency and reduced waste. The long-term ROI typically exceeds 300-400%.

What industries in Nigeria benefit most from lean manufacturing? All manufacturing industries benefit, but food processing, textiles, pharmaceuticals, and automotive assembly show particularly strong results. The key is adapting lean principles to specific industry requirements and local market conditions.

How does lean manufacturing help with Nigeria’s power challenges? Lean manufacturing improves energy efficiency through waste elimination and process optimization. Companies often reduce power consumption by 15-25% while implementing flexible production schedules that work around power instability.

What role do employees play in lean manufacturing success? Employee engagement is crucial for lean success. Nigerian manufacturers that involve workers in identifying problems and developing solutions see 40-50% higher success rates than those that impose changes from management alone.

Can lean manufacturing work with Nigerian supply chains? Yes, but requires adaptation of traditional just-in-time concepts. Successful companies implement modified pull systems and develop supplier partnerships while maintaining appropriate buffer stocks for critical materials.

How does lean manufacturing affect product quality in Nigeria? Lean manufacturing typically improves product quality by 30-50% through systematic problem-solving and error prevention. This improvement helps Nigerian manufacturers compete more effectively in both domestic and export markets.

What support is available for lean manufacturing in Nigeria? Professional consulting firms like Novatia Consulting provide comprehensive support including assessment, implementation, training, and ongoing guidance. Government agencies and industry associations also offer resources and networking opportunities for lean manufacturers.